HAOSAIL cuenta con más de 10 patentes de invención y 40 patentes de modelos de utilidad, lo que refleja nuestro compromiso con la I+D y el avance tecnológico.

Priorizamos rigurosos procesos de control de calidad y pruebas para garantizar el cumplimiento de las normas internacionales y los requisitos del cliente.

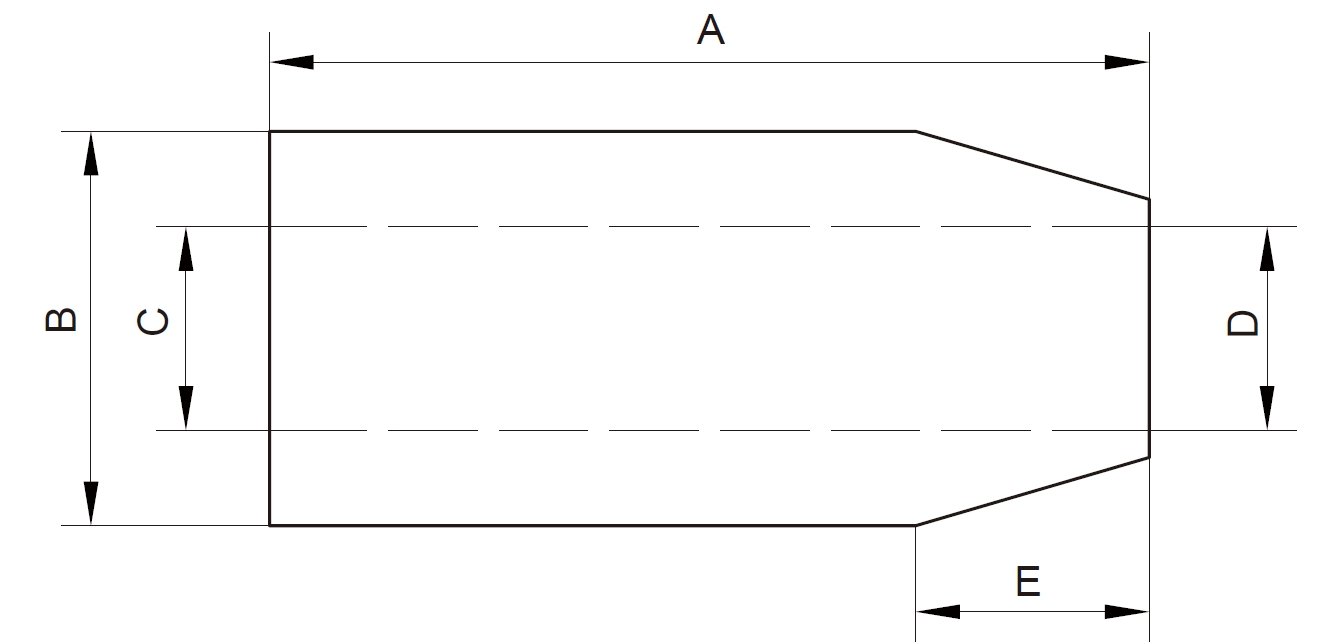

Flemish EYE Steel Swaging Sleeves (S - 505) are key accessories designed for wire rope splicing systems and are made of high-quality carbon steel. After machining and cold extrusion, the surface is usually black-oxidized to enhance corrosion resistance. Its specifications range from 1/4 inch to 6 inches, and special sizes can also be customized. This sleeve forms a rope loop at the end of the wire rope through an extrusion process. It is compatible with wire ropes of various structures such as ips, xip (eip), rrl, fc, iwrc, etc., and plays an important role in various scenarios involving wire rope connection and fixation.

| Stock no. | For wire size (in) | Dimensions (in) | Max.afterswage dimensions (in) | Weight 100pcs/lbs | ||||

| A | B | D | E | C | ||||

| HS2061201 | 1/4 | 1 | 0.66 | 0.31 | 0.28 | 0.47 | 0.57 | 2.27 |

| HS2061202 | 5/16 | 1.5 | 0.91 | 0.38 | 0.44 | 0.62 | 0.75 | 6.36 |

| HS2061203 | 3/8 | 1.5 | 0.91 | 0.47 | 0.39 | 0.66 | 0.75 | 6.36 |

| HS2061204 | 7/16 | 2 | 1.22 | 0.53 | 0.65 | 0.85 | 1.01 | 15 |

| HS2061205 | 1/2 | 2 | 1.22 | 0.63 | 0.56 | 0.91 | 1.01 | 13 |

| HS2061206 | 9/16 | 2.75 | 1.47 | 0.7 | 0.63 | 1.03 | 1.24 | 29 |

| HS2061207 | 5/8 | 2.75 | 1.47 | 0.75 | 0.63 | 1.09 | 1.24 | 26 |

| HS2061208 | 3/4 | 3.19 | 1.72 | 0.91 | 0.84 | 1.28 | 1.46 | 40 |

| HS2061209 | 7/8 | 3.56 | 2.03 | 1.03 | 1 | 1.53 | 1.68 | 60 |

| HS2061210 | 1 | 4 | 2.28 | 1.16 | 1.13 | 1.72 | 1.93 | 89 |

| HS2061211 | 1-1/8 | 4.8 | 2.5 | 1.28 | 1.25 | 1.94 | 2.13 | 118 |

| HS2061212 | 1-1/4 | 5.19 | 2.78 | 1.44 | 1.41 | 2.16 | 2.32 | 161 |

| HS2061213 | 1-3/8 | 5.81 | 3 | 1.56 | 1.56 | 2.38 | 2.52 | 192 |

| HS2061214 | 1-1/2 | 6.25 | 3.25 | 1.69 | 1.69 | 2.63 | 2.71 | 227 |

| HS2061215 | 1-3/4 | 7.25 | 3.84 | 1.94 | 1.97 | 3.13 | 3.1 | 366 |

| HS2061216 | 2 | 8.5 | 4.38 | 2.25 | 2.25 | 3.63 | 3.56 | 514 |

| HS2061217 | 2-1/4 | 9.56 | 5.03 | 2.5 | 2.53 | 4.03 | 4.12 | 879 |

| HS2061218 | 2-1/2 | 10.5 | 5.5 | 2.75 | 2.81 | 4.50 | 4.5 | 1068 |

| HS2061219 | 2-3/4 | 11.5 | 5.75 | 3 | 3.09 | 4.75 | 4.7 | 1271 |

| HS2061220 | 3 | 12 | 6 | 3.25 | 3.38 | 5 | 4.96 | 1335 |

| HS2061221 | 3-1/4 | 13 | 6.5 | 3.86 | 3.54 | 5.43 | 5.37 | 1650 |

| HS2061222 | 3-1/2 | 14 | 7 | 3.88 | 3.94 | 5.84 | 5.77 | 2106 |

| HS2061223 | 3-3/4 | 15 | 7.5 | 4.06 | 4.25 | 6.31 | 6.23 | 2497 |

| HS2061224 | 4 | 16 | 8.13 | 4.38 | 4.50 | 6.81 | 6.69 | 3087 |

| HS2061225 | 4-1/2 | 18 | 9.13 | 4.88 | 5.06 | 7.66 | 7.45 | 4540 |

| HS2061226 | 5 | 20 | 10.52 | 5.5 | 5.63 | 8.73 | 8.28 | 6600 |

| HS2061227 | 6 | 24 | 12.54 | 6.5 | 6.75 | 10 | 9.93 | 12300 |

Excellent low-temperature toughness: It can maintain good performance in low-temperature environments and can be used in operating scenarios that require low-temperature toughness to ensure stable operation of the equipment.

Strong anti-cracking performance: During the extrusion molding process, it shows excellent anti-cracking characteristics, and its performance is equivalent to or even exceeds that of stainless steel casing, ensuring the durability and reliability of the product.

Advantages of cold extrusion process: Cold extrusion gives it good processing performance. After extrusion, the casing surface can be marked and no cracks will appear, which is convenient for product traceability and inspection.

Excellent material: High-quality carbon steel is selected, with high strength and can withstand large tension, providing reliable protection for wire rope connection.

Lifting and hoisting operations: commonly used for inserting the winding ring of the wire rope, fixing the end of the wire rope on the lifting equipment such as tower cranes and elevators in construction, and cranes, electric hoists and other equipment in industrial production to ensure the safety of heavy lifting.

Shipbuilding and marine engineering: in the rigging system of ships such as sailboats and yachts, it is used to make wire rope rings, connect the rigging and the hull, and withstand the tension during navigation; in the lifting and mooring operations of the offshore platform, it also plays an important role in connection and fixing.

Outdoor sports facilities: such as the zip line and cable car in the adventure park, the wire rope carrying tourists is fixed through the wire rope ring made of S-505 casing to provide a safe experience for tourists.

Q1: ¿Cómo elegir la especificación correcta?

Elija según la carga máxima de la operación. Por ejemplo, si levanta una carga de 10 toneladas, debe elegir una especificación de grillete con una carga máxima de trabajo superior a 10 toneladas. Consulte las dimensiones en los parámetros del producto para asegurarse de que sea compatible con los cables, cadenas, etc. conectados.

Q3: ¿Cuál es el rango de temperatura de funcionamiento?

El grillete está certificado para usarse en un entorno de -40 °C (-40 °F) a 204 °C (400 °F). Superar este rango de temperatura puede afectar el rendimiento del material y la seguridad de la conexión.

Q3: ¿Qué precauciones se deben tomar para la instalación y el desmontaje?

Durante la instalación, asegúrese de apretar bien el pasador roscado para evitar que se afloje; durante el desmontaje, evite una operación violenta que pueda dañar la rosca. Antes y durante el uso, revise regularmente el desgaste de la rosca y las grietas en el cuerpo.

Q3: ¿Se pueden proporcionar las certificaciones pertinentes? Algunos fabricantes pueden proporcionar certificados de certificación para estándares específicos como ABS, DNV, Lloyds, etc., que deben solicitarse al realizar un pedido y pueden generar costos adicionales.

Si tiene alguna pregunta o necesidad sobre el producto, rellene el siguiente formulario y nos pondremos en contacto con usted lo antes posible.

Contera

Contera

Contera

Contera

Contera

Contera

Conozca Haosail, nuestras actualizaciones y todas las novedades, directamente en su bandeja de entrada.

Piso 7, Edificio 93, Sede de R&F, n.° 1, Changcheng South Road, Distrito de Chengyang, Ciudad de Qingdao, Provincia de Shandong, China 266109

Copyright © 2025 Qingdao Haosail Machinery Co., Ltd. Todos los derechos reservados. Desarrollado por Hicheng