HAOSAIL cuenta con más de 10 patentes de invención y 40 patentes de modelos de utilidad, lo que refleja nuestro compromiso con la I+D y el avance tecnológico.

Priorizamos rigurosos procesos de control de calidad y pruebas para garantizar el cumplimiento de las normas internacionales y los requisitos del cliente.

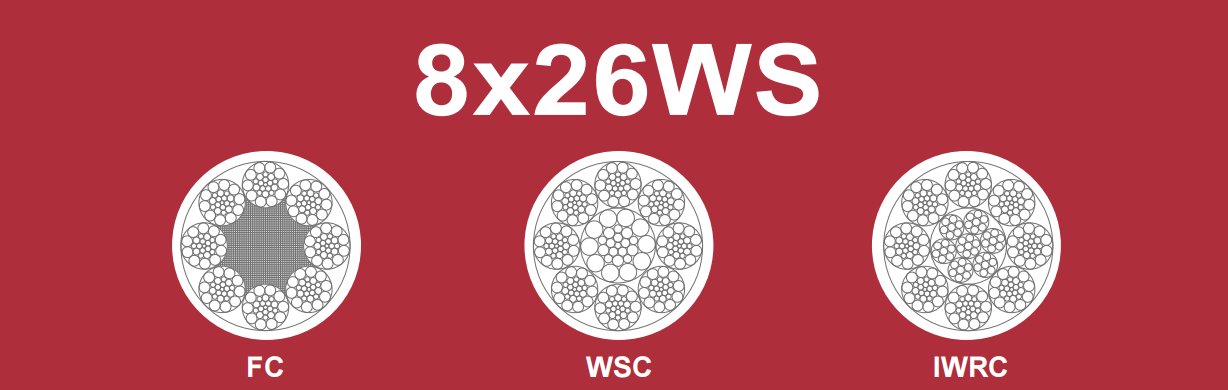

El cable de acero 8X26WS es un producto de alto rendimiento con una estructura de 8 cordones, cada uno de los cuales contiene 26 alambres de acero y adopta la disposición compuesta Warinton-Silo (WS): capa interna tipo Warinton (alternando alambres gruesos y delgados para mayor flexibilidad) y capa externa tipo Silo (todos los alambres gruesos para una alta resistencia al desgaste). Su diseño de 8 cordones mejora la resistencia a la torsión, reduce la rotación durante la operación y es adecuado para múltiples situaciones de dirección. Presenta una alta tensión de rotura, combina resistencia y flexibilidad, y se puede enrollar alrededor de poleas de diámetro medio (≥20 veces el diámetro del cable). Se utiliza ampliamente en condiciones de trabajo de medianas a pesadas, como el abatimiento de grúas, la elevación portuaria y la elevación minera, y es especialmente adecuado para operaciones complejas que requieren resistencia a la torsión, al desgaste y a la flexión.

Cable de acero en contacto con línea (galvanizado y no galvanizado).

Todos los alambres del cable tienen la misma longitud de paso. Cada capa de alambres se coloca en la ranura formada entre los alambres internos. Los alambres están en contacto lineal y la estructura del cable es firme. Por lo tanto, el cable de acero en contacto lineal tiene una gran fuerza de rotura y no se produce tensión de flexión secundaria entre las capas de alambres durante su uso.

Características: El contacto dentro de la hebra es más estrecho que el contacto puntual, el coeficiente de densidad es mayor, la tensión de flexión y contacto en el alambre de acero en la cuerda es menor durante la operación y la vida útil es mayor que la del cable de acero de contacto puntual general.

Estructura del cable de acero: 8*26WS-FC, 8*26WS-IWRC

| N.º de stock | Cuerda nominal | Resistencia nominal a la tracción (MPa) | ||||||||

| - | Tamaño | Carga mínima de rotura (kN) | ||||||||

| FC | IWRC/WSC (≤10 mm WSC) | |||||||||

| mm | en. | kilogramos/100 m | 1770 N/mm2 | 1960 N/mm2 | 2160 N/mm2 | kilogramos/100 m | 1770 N/mm2 | 1960 N/mm2 | 2160 N/mm2 | |

| HS6010101 | 3 | 3.25 | 4.81 | 5.32 | 5.87 | 3,95 | 5.68 | 6.29 | 6.93 | |

| HS6010102 | 4 | 5.77 | 8.55 | 9.5 | 10.4 | 7.03 | 10.1 | 11.2 | 12.3 | |

| HS6010103 | 5 | 9.01 | 13.4 | 14.8 | 16.3 | 11 | 15.8 | 17.5 | 19.2 | |

| HS6010104 | 6 | 13 | 19.2 | 21.3 | 23.5 | 15.8 | 22.7 | 25.1 | 27.7 | |

| HS6010105 | 6.35 | 1/4 | 14.5 | 21.5 | 23.9 | 26.3 | 17.7 | 25.4 | 28.2 | 31 |

| HS6010106 | 7 | 17.7 | 26.2 | 29 | 31.9 | 21.5 | 30.9 | 34.2 | 37.7 | |

| HS6010107 | 7.94 | 5/16 | 22.7 | 33.7 | 37.3 | 41.1 | 27.7 | 39.8 | 44 | 48.5 |

| HS6010108 | 8 | 23.1 | 34.2 | 37.9 | 41.7 | 28.1 | 40.4 | 44.7 | 49.3 | |

| HS6010109 | 9 | 29.2 | 43.3 | 47.9 | 52.8 | 35.6 | 51.1 | 56.6 | 62.4 | |

| HS6010110 | 9.5 | 3/8 | 32.5 | 48.2 | 53.4 | 58.8 | 39.7 | 56.9 | 63 | 69.5 |

| HS6010111 | 10 | 36.1 | 53.4 | 59.2 | 65.2 | 43.9 | 63.1 | 69.9 | 77 | |

| HS6010112 | 11 | 43.6 | 64.6 | 71.6 | 78.9 | 53.2 | 76.3 | 84.5 | 93.1 | |

| HS6010113 | 11.1 | 7/16 | 44.4 | 65.8 | 72.9 | 80.3 | 54.1 | 77.7 | 86.1 | 94.8 |

| HS6010114 | 12 | 51.9 | 76.9 | 85.2 | 94 | 63.3 | 90.8 | 101 | 111 | |

| HS6010115 | 12.7 | 1/2 | 58.2 | 86.2 | 95 | 105 | 70.9 | 102 | 113 | 124 |

| HS6010116 | 13 | 60.9 | 90.3 | 100 | 110 | 74.3 | 107 | 118 | 130 | |

| HS6010117 | 14 | 70.7 | 105 | 116 | 128 | 86.1 | 124 | 137 | 151 | |

| HS6010118 | 14.3 | 9/16 | 73.7 | 109 | 121 | 133 | 89.8 | 129 | 143 | 157 |

| HS6010119 | 15.9 | 5/8 | 91.2 | 135 | 150 | 165 | 111 | 159 | 177 | 195 |

| HS6010120 | 16 | 92.3 | 137 | 151 | 167 | 112 | 161 | 179 | 197 | |

| HS6010121 | 18 | 117 | 173 | 192 | 211 | 142 | 204 | 226 | 249 | |

| HS6010122 | 19 | 130 | 193 | 214 | 235 | 159 | 228 | 252 | 278 | |

| HS6010123 | 19.1 | 3/4 | 132 | 195 | 216 | 238 | 160 | 230 | 255 | 281 |

| HS6010124 | 20 | 144 | 214 | 237 | 261 | 176 | 252 | 279 | 308 | |

| HS6010125 | 22 | 175 | 259 | 286 | 316 | 213 | 305 | 338 | 373 | |

| HS6010126 | 22.2 | 7/8 | 178 | 263 | 292 | 321 | 217 | 311 | 344 | 379 |

| HS6010127 | 24 | 208 | 308 | 341 | 375 | 253 | 363 | 402 | 443 | |

| HS6010128 | 25.4 | 1 | 233 | 345 | 382 | 421 | 283 | 407 | 451 | 497 |

| HS6010129 | 26 | 244 | 361 | 400 | 441 | 297 | 426 | 472 | 520 | |

| HS6010130 | 28 | 283 | 419 | 464 | 511 | 344 | 495 | 548 | 604 | |

| HS6010131 | 28.6 | 1 1/8 | 295 | 437 | 484 | 533 | 359 | 516 | 571 | 630 |

| HS6010132 | 31.8 | 1 1/4 | 365 | 540 | 598 | 659 | 444 | 638 | 706 | 778 |

| HS6010133 | 32 | 369 | 547 | 606 | 668 | 450 | 646 | 715 | 788 | |

| HS6010134 | 34.9 | 1 3/8 | 439 | 651 | 720 | 794 | 535 | 768 | 851 | 938 |

| HS6010135 | 35 | 442 | 654 | 725 | 799 | 538 | 773 | 856 | 943 | |

| HS6010136 | 36 | 467 | 692 | 767 | 845 | 569 | 818 | 905 | 998 | |

| HS6010137 | 38 | 521 | 771 | 854 | 941 | 634 | 911 | 1009 | 1112 | |

| HS6010138 | 38.1 | 1 1/2 | 523 | 775 | 859 | 946 | 638 | 916 | 1014 | 1117 |

| HS6010139 | 40 | 577 | 855 | 946 | 1043 | 703 | 1009 | 1118 | 1232 | |

| HS6010140 | 41.3 | 1 5/8 | 615 | 911 | 1009 | 1112 | 749 | 1076 | 1191 | 1313 |

| HS6010141 | 44 | 698 | 1034 | 1145 | 1262 | 851 | 1221 | 1352 | 1490 | |

| HS6010142 | 44.5 | 1 3/4 | 714 | 1058 | 1171 | 1291 | 870 | 1249 | 1383 | 1524 |

| HS6010143 | 45 | 730 | 1082 | 1198 | 1320 | 890 | 1277 | 1414 | 1559 | |

| HS6010144 | 47.6 | 1 7/8 | 817 | 1210 | 1340 | 1477 | 995 | 1429 | 1583 | 1744 |

| HS6010145 | 48 | 831 | 1231 | 1363 | 1502 | 1012 | 1453 | 1609 | 1774 | |

| HS6010146 | 50.8 | 2 | 931 | 1378 | 1526 | 1682 | 1134 | 1628 | 1803 | 1987 |

| HS6010147 | 51 | 938 | 1389 | 1539 | 1696 | 1143 | 1641 | 1817 | 2002 | |

| HS6010148 | 52 | 975 | 1444 | 1599 | 1763 | 1188 | 1706 | 1889 | 2081 | |

| HS6010149 | 54 | 2 1/8 | 1051 | 1558 | 1725 | 1901 | 1281 | 1839 | 2037 | 2245 |

| HS6010150 | 56 | 1131 | 1675 | 1855 | 2044 | 1378 | 1978 | 2191 | 2414 | |

| HS6010151 | 57.2 | 2 1/4 | 1180 | 1748 | 1935 | 2133 | 1437 | 2064 | 2285 | 2519 |

| HS6010152 | 60 | 1298 | 1923 | 2129 | 2347 | 1582 | 2271 | 2515 | 2771 | |

| HS6010153 | 60.3 | 2 3/8 | 1311 | 1942 | 2151 | 2370 | 1598 | 2294 | 2540 | 2799 |

| HS6010154 | 62 | 1386 | 2053 | 2274 | 2506 | 1689 | 2425 | 2685 | 2959 | |

| HS6010155 | 63.5 | 2 1/2 | 1454 | 2154 | 2385 | 2628 | 1772 | 2544 | 2817 | 3104 |

| HS6010156 | 64 | 1477 | 2188 | 2423 | 2670 | 1800 | 2584 | 2861 | 3153 | |

8-strand anti-twist design: Compared with the 6-strand structure, the symmetrical arrangement of 8 strands greatly reduces the rotational torque during operation, which is especially suitable for multi-turn and long-distance traction scenarios, reducing rope damage caused by torsion.

WS composite strand performance: The alternating thick and thin steel wires in the inner layer of each strand (Warrington type) improve flexibility, and the outer layer of all thick steel wires (Sirru type) enhances wear resistance, taking into account bending flexibility and wear resistance.

Medium load adaptability: The breaking tension is suitable for medium and heavy loads (25-60 tons). When used with a pulley with a rope diameter of more than 20 times, the fatigue resistance is better than that of a 6-strand rope of the same specification.

Uniform force distribution: The 8-strand structure makes the wire rope contact with the pulley/drum more closely, with less pressure per unit area, which can reduce local wear and extend the life under frequent retraction and release conditions.

Flexible choice of core material: supports fiber core (FC, suitable for low-impact and vibration-reducing scenarios) or steel core (IWRC, suitable for high temperature and heavy load environments), and performance can be customized according to operating conditions.

8×26WS wire rope is suitable for medium and heavy duty, multi-turn or anti-rotation scenes with the characteristics of "8-strand anti-twist, WS composite strands are wear-resistant and flexible", and typical applications include:

Crane field: 30-60 ton truck crane main and auxiliary hook lifting, crawler crane luffing mechanism, especially suitable for long-distance boom and frequent turning conditions, reducing the swing of the hanging objects caused by rotation.

Ports and docks: traction ropes of small and medium-sized container gantry cranes and hoisting systems of floating cranes can adapt to the complex turning of multiple pulleys and withstand seawater environment (select steel core IWRC to enhance corrosion resistance).

Mines and tunnels: hoists in medium and deep mines (lifting height 800-1500 meters) are used for cage or mine car traction. The 8-strand structure can reduce the torsional stress when winding the drum, and cooperate with the steel core to improve the load-bearing capacity.

Engineering traction and tensioning: translational traction of precast beams of large bridges, temporary tie ropes for hoisting steel structures of high-rise buildings, taking into account high strength and torsion resistance to avoid knotting of the rope during traction.

Ropeways and elevators: load-bearing traction ropes of small and medium-sized freight ropeways, traction systems of heavy-load elevators (such as freight elevators and sightseeing elevators), suitable for multi-wheel steering and stable operation.

Q1: How does the "torsion resistance" of 8×26WS perform specifically? What are its advantages compared to 6-strand ropes?

A: The symmetrical arrangement of the 8 strands of 8×26WS can greatly offset the torsional stress during operation. Compared with 6-strand ropes (such as 6×36WS):

The "rotation angle" of long-distance suspension (such as when the crane boom is extended) is reduced by 40%-60%, preventing the hanging objects from shaking due to the rotation of the wire rope;

When multiple layers are wound on the drum, it is not easy to cause "rope skipping" or "rope chaos" due to torque accumulation, which is especially suitable for long-distance traction scenarios (such as mine hoisting).

Q5: To what extent does the outer thick steel wire need to be replaced after wear?

A: The outer thick steel wire is the main wear-resistant part and needs to be monitored:

If the diameter of a single steel wire is worn more than 30% of the original diameter (e.g. the original diameter is 1.5mm, and after wear it is ≤1.05mm), even if the wire is not broken, the inspection cycle needs to be shortened (from once a month to once a week);

If "groove-shaped wear" (depth> 0.5mm) occurs locally, or more than 3 strands of a single outer thick steel wire are broken, it needs to be scrapped immediately (thin steel wire cannot bear the outer wear-resistant task alone).

Q5: Is 8×26WS suitable for high-frequency forward and reverse reel?

A: It is suitable, but two conditions must be met:

The reel diameter is ≥20 times the rope diameter (e.g. a 20mm rope requires a ≥400mm reel), and excessive bending should be avoided to cause fatigue of the inner steel wire;

Ensure that the rope groove of the reel is smooth and burr-free, and the deceleration is smooth when switching between forward and reverse directions (avoid instantaneous torque shock), otherwise the alternation of the outer thick and thin steel wires is prone to accelerated aging due to frictional heat.

Si tiene alguna pregunta o necesidad sobre el producto, rellene el siguiente formulario y nos pondremos en contacto con usted lo antes posible.

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Cable de acero

Conozca Haosail, nuestras actualizaciones y todas las novedades, directamente en su bandeja de entrada.

Piso 7, Edificio 93, Sede de R&F, n.° 1, Changcheng South Road, Distrito de Chengyang, Ciudad de Qingdao, Provincia de Shandong, China 266109

Copyright © 2025 Qingdao Haosail Machinery Co., Ltd. Todos los derechos reservados. Desarrollado por Hicheng